We love your challenges!

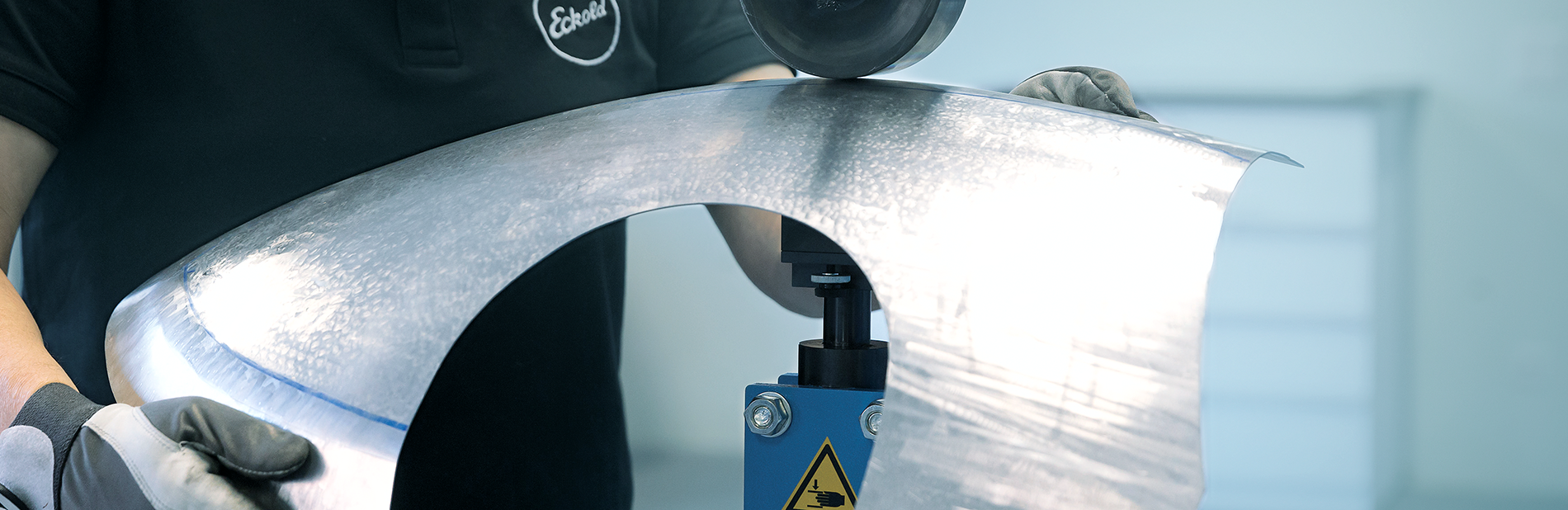

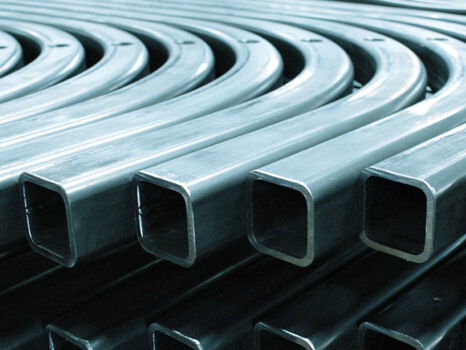

Whether it’s 2D or 3D bending, curve bending or mandril bending of profiles, pipes or sheet metal, we have the right solution for various industries – even for tricky bending projects. We create simple radii from a wide variety of geometries, generate multiple radii or manufacture individual curves. Feel free to challenge us – we will quickly prove to you our expertise and many years of experience.